Newest 3 In 1 Copper 220V Processing Busbar Bender Beading Machine

- Packaging:

- Ply wooden cases

- Brand:

- Zhuoxun

- Place of Origin:

- Zhejiang, China (Mainland)

Basic Info

Model No.: ZXMX-16200

Product Description

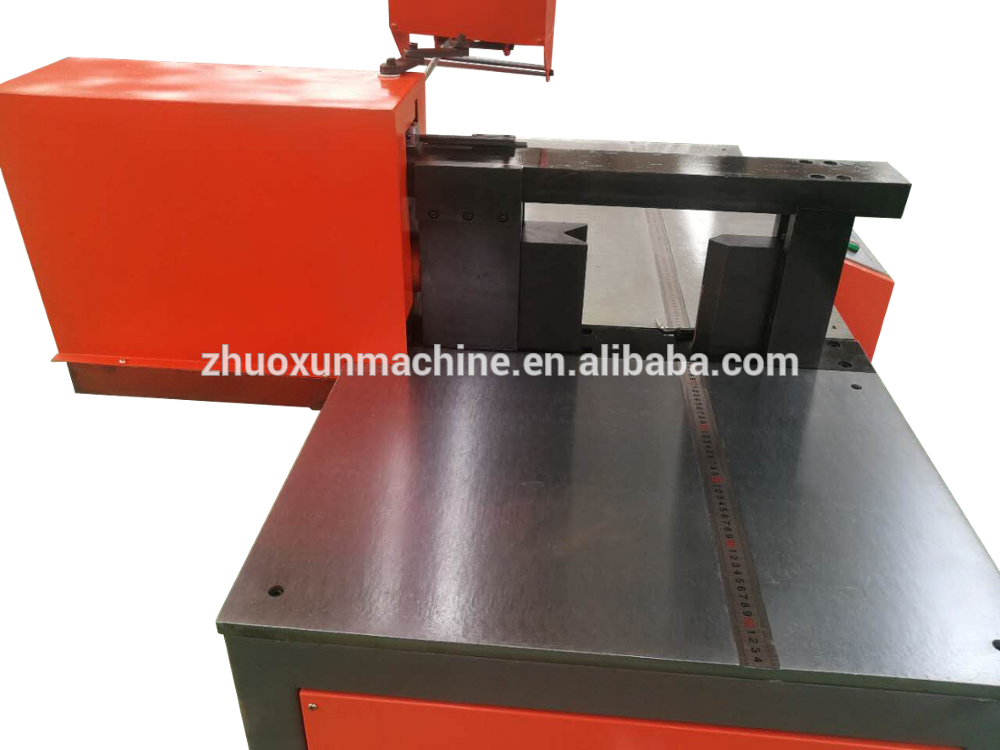

ZXMX-12160/ZXMX-16200/ZXMX-20260 Cnc Busbar Machine

1.This machine is a customize machine, they are respectly are CNC Bending Machine, turrent Punching Machine, cutting machine. The processing size of 160200*16mm copper and aluminum plate. It has the functions like flating bending, vertical bending, cutting, embossing punching,( 54560532,circular hole and oblong hole). The big feature is that three sets machine can place at random, and work without affect Others, they will work without effect of of the size of the busbar and space, efficiency is obviously higher than a traditional one. It suit the big space and mass production.

2.The hydraulic busbar cutting machine use sharp cutting, the incision interface is flat, no droop, burrs and waste.

3.The CNC busbar bending machine can do horizontal bending and vertical bending.CNC controls the bending angle by an imported PLC contact system.Input a busbar thickness and an angle on a CNC touching screen,or input a height and a side length to get the result what you need,such as Z bending.Bending precision is ±1°,repeat precision is ±0.3°,the user can input processing date in advance,and the system will do the process according to inputted date.The field date can be put into the system at any time and be paged out for using repeatedly.

4.The busbar punching machine use an united six mode turn plate tooth shape to make sure the upper mode and the lower mode are absolutely in the center. Improve the mould concentricity and longer the working life. The turn plate is in tooth shape with good view and high strength. No need to frequently change molds, labor intensity is highly reduced, it is easy and quick to use. Producing efficiency is obviously higher than a traditional one.

Function | Item | ZX-12160 | ZX-16200 | ZX-20260 |

Vertical Bending | Max. Bending Force (KN) | 300 | 500 | 800 |

Max. Thickness (MM) | 12 | 16 | 20 | |

Max. Width (MM) | 160 | 200 | 260 | |

Horizontal Bending | Max. Width (MM) | 120 | 120 | 120 |

Max. Angle (Degree) | 90° | 90° | 90° | |

Out Dimension | MM | 1620*1350*1300 | 1750*1550*1380 | 1950*1730*1450 |

Power | KW | 4kw | 5.5kw | 5.5kw |

Weight | KG | 820kg | 1100kg | 1300kg |

CNC Precision | Bending Precision | ±1° | ±1° | ±1° |

Repeat Bending Precision | ±0.3° | ±0.3° | ±0.3° |

1. What is your payment terms?

A.30% TT as deposit, balance be paid when goods are ready for loading before shipment.

B.L/C.

2. What is your delivery time?

Usually within 7-15 days after the deposit.

3. What is your power supply?

We will adjust according to your countries power supply, such as 220V, 380V and 415V.

4. What is your Min order quantity?

One set. Our customers can be end users, retailers and wholesalers.

5. What is machine warranty time?

The warranty time is 2 years for the machine and tools, the vulnerable parts warranty time is 1 year.

6.How do you ship the tools and machines and how long does it take to arrive?

We usually ship by sea. It usually takes 30 days to arrive. Airline shipping also optional.

Product Categories : CNC Busbar Machine

Premium Related Products