China best panel cnc fabricated low price brass busbar machine Shearing Machine

- Packaging:

- in open top container

- Brand:

- Zhuoxun

- Place of Origin:

- Zhejiang, China (Mainland)

Basic Info

Model No.: QC12K 4x2500, QC12K SERIES

Product Description

QC12K sheet metal Shearing Machine steel plate machine

Qc12k hydraulic steel guillotine shearing machine with 500mm distance back gauge

Main Features:

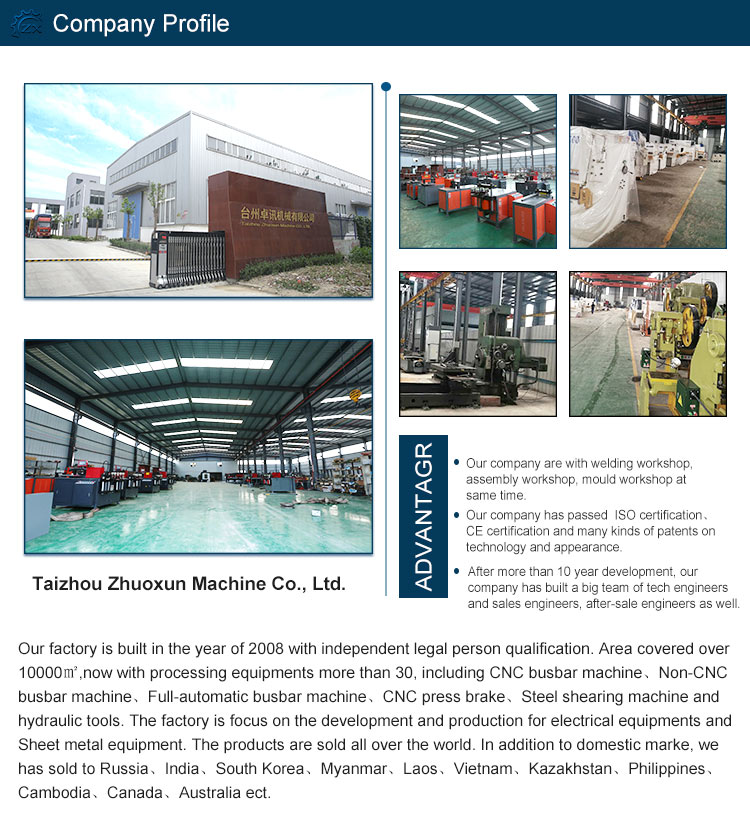

1.Totally EU streamlined design,monoblock by welding robots & apparatus and stress relief process by Annealing treatment.

2.Zhuoxun engineers utilize parametric 3D Solid-Works using FEM & DOE analysis as well as static and mechanism analysis.

3.Zhuoxun Hydraulic Shearing Machine is a Swing Beam Action machine which is produced in a variety of cutting lengths and capacity options.

3. Adopt integrated hydraulic system, more reliable and easy for maintenance. and the hydraulic system from Bosch-Rexroth, Germany,

4. Equipped with lighting-alignment, so as to align when shearing. The stroke of knife beam can be adjusted in stepless mode.

5. Hydraulic drive, return of knife beam is smooth and prompt by nitrogen cylinder.

6. CE conformity including Tiltable Fornt Finger Guard and Optical Rear Safety Guard,

7. Safe fence and the electric inter locker have been designed for the machine to

ensure the operation safety.

Standard Equipment:

1. Rapid and precise blade clearance adjustment by single handle on the side frame

2. Multi Edge Blades for cutting Aluminium, Mild Steel and Stainless Steel

3. Cutting Line Illumination and wire for shadow line cutting

4. Counter of Strokes, Cutting Length Adjustment

5. Hydraulic and Electrical overload protection

6. Squaring Arm and Front Support Arms

7. Estun E21s NC control

8. Germany Bosch-Rexroth Hydraulic

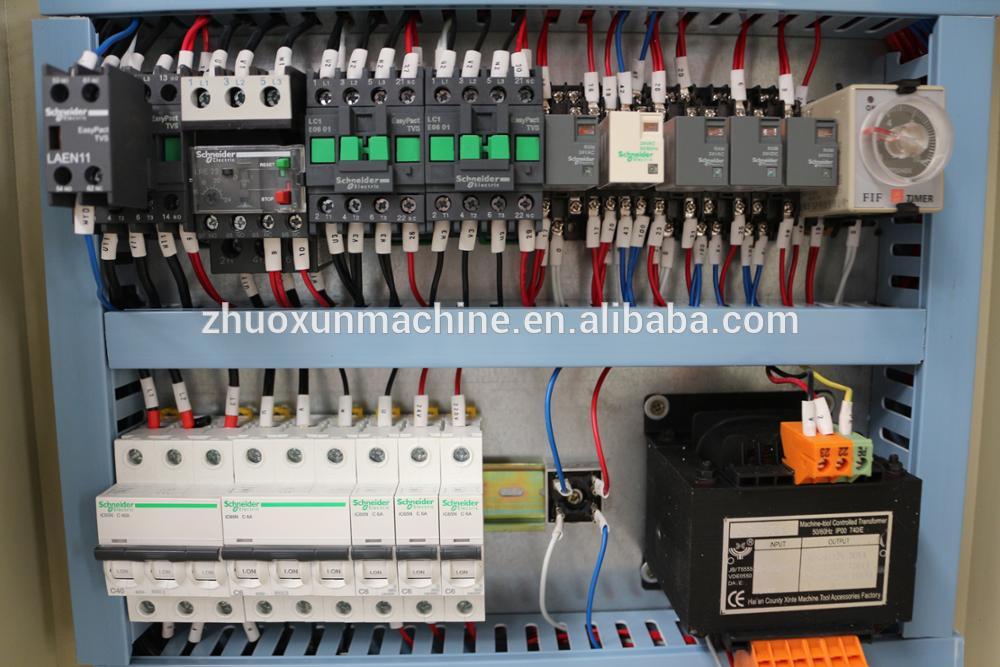

9. Telemecanique/SchneiderElectrics

10. Hydraulic and Electrical overload protection

11. Delta inverter with ball screw and polished rod with 0,05 mm accuracy.

12. Side guard is standard meeting CE regulations.

Better Cuttings:

1.Backgauge adjustment according to blade gap.

2.Backgauge retraction feature.

3.Sub-program and programming loop.

4.Sequence repeat function.

5.Auto cutting (Flying cut).

Estun E21s NC Shearing Machine Control system:

1. Monochrome LCD Box Panel.

2. Integral factor programmable freely

3. Automatic positioning control

4.Spindle allowance offset

5.Internal time relay

6.Stock counter

7.Backgauge position display, resolution in 0.05mm

The best cutting results You can cut longer and narrow parts with standard AC/MS7-Cutt Series.

Qc12k hydraulic steel guillotine shearing machine with 500mm distance back gauge.

Performance

Powered Back gauge X-axis

DELTA Inverter controlled back gauge

HIWIN Ball screws & Polished rod with 0,05 mm accuracy.

Squaring Arm and Front Support Arms

Germany Bosch-Rexroth Hydraulic

Germany EMB Tubing connector

Germany Siemens Main Motor

Telemecanique/Schneider Electrics

Hydraulic & Electrical overload protection

Cutting Line Illumination and wire for shadow line cutting

Top blade with two cutting edges and bottom blade with four cutting edges. (6CrW2Si)

| Model | Shearing Thickness | Shearing Plate Width | Shearing Angle | Material Strength | Travel Number | Power of Main Motor | Weight | Dimensions (Length*Width*Height) |

| (mm) | (mm) | (°) | (KN/CM) | (Number/Min) | (kw) | (kg) | mm | |

| 4x2500 | 4 | 2500 | 1°30′ | ≤450 | 10 | 5.5 | 3800 | 3040x1610x1620 |

| 4x3200 | 4 | 3200 | 1°30′ | ≤450 | 10 | 5.5 | 5000 | 3840x1610x1620 |

| 4x4000 | 4 | 4000 | 1°30′ | ≤450 | 8 | 5.5 | 6500 | 4600x1700x1700 |

| 4x6000 | 4 | 6000 | 1°30′ | ≤450 | 5 | 7.5 | 11000 | 6460x2100x3200 |

| 6x2500 | 6 | 2500 | 1°30′ | ≤450 | 10 | 7.5 | 5000 | 3040x1610x1620 |

| 6x3200 | 6 | 3200 | 1°30′ | ≤450 | 9 | 7.5 | 6000 | 3840x1610x1620 |

| 6x4000 | 6 | 4000 | 1°30′ | ≤450 | 8 | 7.5 | 8200 | 4620x1750x1700 |

| 6x5000 | 6 | 5000 | 1°30′ | ≤450 | 6 | 7.5 | 10500 | 5400x1750x1700 |

| 6x6000 | 6 | 6000 | 1°30′ | ≤450 | 5 | 11 | 16500 | 6480x2100x2300 |

| 8x2500 | 8 | 2500 | 1°30′ | ≤450 | 10 | 7.5 | 6000 | 3040x1700x1700 |

| 8x3200 | 8 | 3200 | 1°30′ | ≤450 | 8 | 7.5 | 7200 | 3860x1700x1700 |

| 8x4000 | 8 | 4000 | 1°30′ | ≤450 | 8 | 7.5 | 8800 | 4640x1700x1700 |

| 8x5000 | 8 | 5000 | 1°30′ | ≤450 | 8 | 7.5 | 11500 | 5400x2400x2000 |

| 8x6000 | 8 | 6000 | 1°30′ | ≤450 | 8 | 11 | 18000 | 6480x2100x2350 |

| 10x2500 | 10 | 2500 | 1°30′ | ≤450 | 9 | 11 | 7300 | 3040x1700x1700 |

| 10x3200 | 10 | 3200 | 2° | ≤450 | 9 | 11 | 8000 | 3860x1700x1700 |

| 10x4000 | 10 | 4000 | 2° | ≤450 | 8 | 11 | 12050 | 4650x2100x2000 |

| 10x6000 | 10 | 6000 | 1°30′ | ≤450 | 5 | 15 | 24000 | 6500x2100x2300 |

| 12x2500 | 12 | 2500 | 1°40′ | ≤450 | 9 | 18.5 | 9000 | 3140x2150x2000 |

| 12x3200 | 12 | 3200 | 1°40′ | ≤450 | 9 | 18.5 | 10800 | 3880x2150x2000 |

| 12x4000 | 12 | 4000 | 1°40′ | ≤450 | 8 | 18.5 | 13000 | 4680x2150x2000 |

| 12x5000 | 12 | 5000 | 2° | ≤450 | 6 | 18.5 | 16000 | 5900x2150x2000 |

| 12x6000 | 12 | 6000 | 2° | ≤450 | 5 | 18.5 | 29500 | 6900x2600x2700 |

| 12x8000 | 12 | 8000 | 2° | ≤450 | 5 | 18.5 | 46500 | 9000x3500x3500 |

| 16x2500 | 16 | 2500 | 2°30′ | ≤450 | 9 | 18.5 | 11000 | 3140x2150x2000 |

| 16x3200 | 16 | 3200 | 2°30′ | ≤450 | 8 | 18.5 | 13000 | 3880x2150x2000 |

| 16x4000 | 16 | 4000 | 2°30′ | ≤450 | 8 | 18.5 | 16300 | 4650x2150x2200 |

| 16x5000 | 16 | 5000 | 2°30′ | ≤450 | 6 | 18.5 | 20000 | 5900x2600x2700 |

| 16x6000 | 16 | 6000 | 2°30′ | ≤450 | 5 | 22 | 36000 | 6900x2700x2700 |

| 16x8000 | 16 | 8000 | 2°30′ | ≤450 | 5 | 22 | 75000 | 9000x3500x3500 |

| 20x2500 | 20 | 2500 | 3° | ≤450 | 8 | 22 | 15800 | 3440x2300x2500 |

| 20x3200 | 20 | 3200 | 3° | ≤450 | 8 | 22 | 18500 | 4150x2350x2700 |

| 20x4000 | 20 | 4000 | 3° | ≤450 | 5 | 22 | 21500 | 4850x2600x2400 |

| 20x6000 | 20 | 6000 | 3° | ≤450 | 4 | 22 | 47000 | 6700x3000x3000 |

| 25x2500 | 25 | 2500 | 3° | ≤450 | 8 | 37 | 19000 | 3200x2700x2900 |

| 25x3200 | 25 | 3200 | 3° | ≤450 | 5 | 37 | 23000 | 4200x2500x2600 |

| 30x2500 | 30 | 2500 | 3° | ≤450 | 4 | 37 | 23500 | 3300x2900x3000 |

| 30x3200 | 30 | 3200 | 3°30′ | ≤450 | 4 | 40 | 26000 | 4200x2500x2600 |

| 40x2500 | 40 | 2500 | 4° | ≤450 | 3 | 75 | 38000 | 3200x3300x3200 |

| 40x3200 | 40 | 3200 | 4° | ≤450 | 3 | 90 | 49000 | 4300x3300x3000 |

Note: these data listed above are only for reference. In case of any consistence with the actual data of the machine tool, the actual data of the machine tool shall prevail. All parameters are subject to change without notice. The company reserves the right to the interpretation of the above data.

1. What is your payment terms?

A.30% TT as deposit, balance be paid when goods are ready for loading before shipment.

B.L/C.

2. What is your delivery time?

Usually within 7-15 days after the deposit.

3. What is your power supply?

We will adjust according to your countries power supply, such as 220V, 380V and 415V.

4. What is your Min order quantity?

One set. Our customers can be end users, retailers and wholesalers.

5. What is machine warranty time?

The warranty time is 2 years for the machine and tools, the vulnerable parts warranty time is 1 year.

6.How do you ship the tools and machines and how long does it take to arrive?

We usually ship by sea. It usually takes 30 days to arrive. Airline shipping also optional.

Product Categories : Shearing Machine > QC12K

Premium Related Products