2017 Top We67K 160/2500 Knife New Press Brake

- Brand:

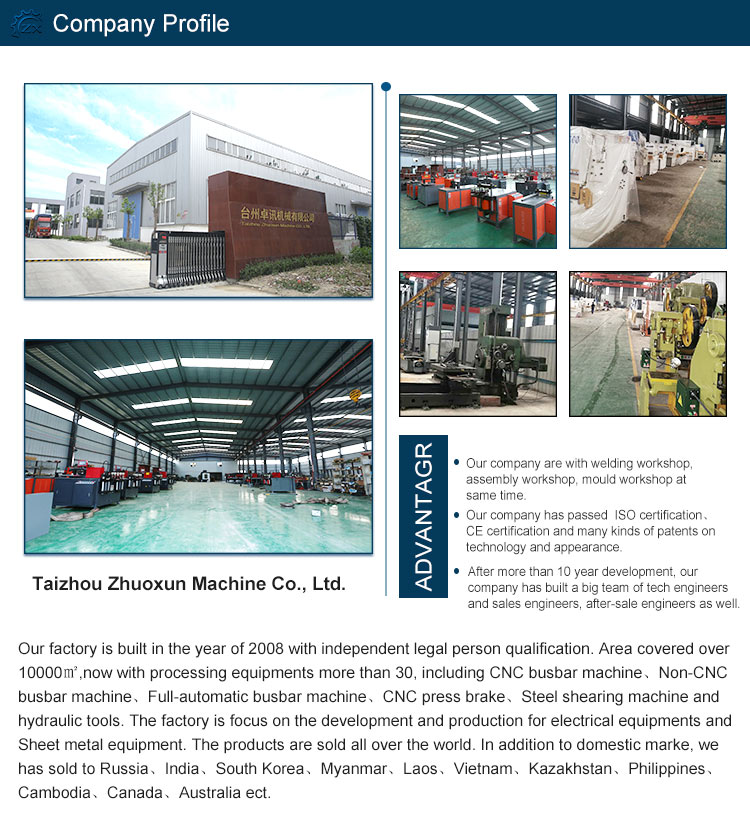

- Zhuoxun

- Place of Origin:

- Zhejiang, China (Mainland)

Basic Info

Model No.: WE67K 160/2500, WE67K Machine

Product Description

hot sale sheet metal plate Press Brake CNC hydraulic Bending Machine

Features:

1. The machine body adopts the structure of integrally weld and integrated machining, and the main parts of the machine body use ANSYS finite element analysis software to analyze, which ensures the reliability of the machine and the precision of the entire machine.

2.The main oil cylinders fitted on both sides adopt closed loop control mode which is composed of Germany electro-hydraulic servo valve and imported grating ruler, breaking through the stroke control mode of traditional mechanical stop bending machines, ensuring the high precision of the glide position feedback, the accurate and stable operation, the high precision of bending and high precision of the repeated positioning of slider.

3.The functional components of the blocking behind press are all imported,ensuring the stopping precision of the blocking behind press.The machine also can adopt more functional multi axis blocking behind press8 mechanism according to the customers' requirements.

4.The hydraulic system adopts integrated control system imported from Germany,which decreases the installation of pipelines and ensures working stability of the machine tool and conciseness and beauty in appearance.

5.C-shaped plates are fitted on both sides of the machine body,and the high precision grating ruler is fitted on the C-shaped plate.Thus to avoid the influences on bending precision arising from distortion of machine body during bending process.

6.The lower workbench is fitted with hydraulic automatic deflection compensation mechanism,ensuring effective compensation without bling area and high precision of bending,so that long stability is guaranteed.

7. the numerical control system adopts the electro hydraulic servo bending machine CNC system imported from Italian ESA, German DELEME or Swiss CYBELEC, which can achieve the function of graphic programming for bending angle, angle amendment compensation, automatic calculation and adjustment of the bending pressure, automatic calculation of workbench distortion compensation, expending length of work piece, bending pressure of sole pressing, open distance and automatic withdrawal of back gauge and so on.

Standard Equipment:

1. 4- axis Delem DA66T programming mode CNC control.

2.Full synchronisation of Y1 + Y2 axes with proportional hydraulic valve system and constant monitoring by CNC system to +/- 0.01mm accuracy.

3.High precision linear scales for measurement of stroke depth mounted on side frames rather than top beam to prevent any distortion in accuracy as beam comes under load.

4.CNC-controlled X & R-axis as standard ballscrew backgauge with servo drive motors.

5. Light guards.

6. Two micrometric backgauge finger-stops with lateral adjustment.

7.Steel mono-block construction.

8.Polished chrome plated and ground cylinders.

9.Long stroke and large open height dimensions.

10.High approach and return speeds for production bending.

11.Euro style quick release top tool holders with intermediaries including wedges for crowning.

12.88 degree sectionalised goose neck top tool.

13.4 way sectionalised multi vee bottom tool.

14.Double footswitch control and pendant type control arm.

15.AKAS laser tooling guards.

16.Electrically interlocked side guards.

17.Electrically interlocked read access door

18.2 sliding front support arms with linear guide rails for lateral adjustment and hand wheel for height adjustment, 1000mm long from centre of bottom tool vee.

19.Side guard is standard meeting CE regulations.

Delem DA66T CNC Press Brake Control system:

1.2D graphical touch screen programming mode

2.3D visualisation in simulation and production

3.17" high resolution colour TFT

4.Full Windows application suite

5.Delem Modusys compatibility (module scalability and adaptivity)

6.USB, peripheral interfacing

7.User specific application support within the controllers multitasking environment

8.Sensor bending & correction interface

| Item | unit | 63/2500 | 63/3200 | 100/2500 | 100/3200 | 100/4000 | 125/2500 | 125/3200 | 125/4000 | 160/2500 | 160/3200 | 160/4000 |

| Nominal force | kn | 630 | 630 | 1000 | 1000 | 1000 | 1250 | 1250 | 1250 | 1600 | 1600 | 1600 |

| Length of table | mm | 2500 | 3200 | 2500 | 3200 | 4000 | 2500 | 3200 | 4000 | 2500 | 3200 | 4000 |

| Distance between uprights | mm | 2050 | 2700 | 2050 | 2700 | 3200 | 2050 | 2700 | 3200 | 2050 | 2700 | 3200 |

| Throat depth | mm | 300 | 300 | 350 | 350 | 350 | 350 | 350 | 350 | 350 | 350 | 400 |

| Ram stroke | mm | 100 | 100 | 120 | 120 | 120 | 120 | 120 | 120 | 200 | 200 | 200 |

| Max. open height between ram and table | mm | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 450 | 450 | 450 |

| Backgauge stroke | mm | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 600 |

| Idle speed | mm/s | 110 | 110 | 130 | 130 | 130 | 130 | 130 | 130 | 120 | 120 | 120 |

| Work speed | mm/s | 14 | 14 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

| Return speed | mm/s | 120 | 120 | 125 | 125 | 125 | 125 | 125 | 125 | 115 | 115 | 115 |

| Main motor | kW | 5.5 | 5.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 11 | 11 | 11 |

| Overall dimension ( LxWxH ) | mm | 2750 | 3300 | 2750 | 3700 | 4150 | 2750 | 3300 | 4150 | 2750 | 3300 | 4150 |

| 1600 | 1600 | 1750 | 1570 | 1750 | 1750 | 1750 | 1750 | 1800 | 1800 | 1800 | ||

| 2450 | 2650 | 2700 | 2550 | 2750 | 2650 | 2750 | 2800 | 2650 | 2750 | 2800 | ||

| Weight | kg | 6000 | 6600 | 8300 | 9500 | 11000 | 8800 | 10500 | 12000 | 9600 | 11800 | 13200 |

| Item | unit | 200/2500 | 200/3200 | 200/4000 | 250/2500 | 250/3200 | 250/4000 | 320/3200 | 320/4000 | 400/3200 | 400/4000 | 400/5000 |

| Nominal force | kN | 2000 | 2000 | 2000 | 2500 | 2500 | 2500 | 3200 | 3200 | 4000 | 4000 | 4000 |

| Length of table | mm | 2500 | 3200 | 4000 | 2500 | 3200 | 4000 | 3200 | 4000 | 3200 | 4000 | 5000 |

| Distance between uprights | mm | 2050 | 2700 | 3200 | 2050 | 2700 | 3200 | 2700 | 3200 | 2700 | 3200 | 4000 |

| Throat depth | mm | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 |

| Ram stroke | mm | 250 | 250 | 250 | 250 | 250 | 250 | 250 | 250 | 300 | 300 | 300 |

| Max. open height between ram and table | mm | 520 | 520 | 520 | 520 | 520 | 520 | 550 | 550 | 570 | 570 | 570 |

| Backgauge stroke | mm | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 |

| Idle speed | mm/s | 110 | 110 | 110 | 110 | 110 | 110 | 80 | 80 | 80 | 80 | 80 |

| Work speed | mm/s | 10 | 10 | 10 | 10 | 10 | 10 | 8 | 8 | 8 | 8 | 8 |

| Return speed | mm/s | 110 | 110 | 110 | 110 | 110 | 110 | 85 | 85 | 85 | 85 | 85 |

| Main motor | kW | 18.5 | 18.5 | 18.5 | 18.5 | 18.5 | 18.5 | 22 | 22 | 30 | 30 | 30 |

| Overall dimension ( LxWxH ) | mm | 2750 | 3300 | 4150 | 2750 | 3300 | 4150 | 3350 | 4150 | 3470 | 4270 | 5270 |

| 2000 | 2000 | 2000 | 2000 | 2000 | 2000 | 2100 | 2100 | 3200 | 3200 | 3200 | ||

| 2800 | 2910 | 2950 | 2850 | 2930 | 2980 | 3150 | 3200 | 4250 | 4370 | 4710 | ||

| Weight | kg | 10000 | 14500 | 16000 | 12800 | 15000 | 17800 | 19600 | 22200 | 24000 | 26000 | 32000 |

1. What is your payment terms?

A.30% TT as deposit, balance be paid when goods are ready for loading before shipment.

B.L/C.

2. What is your delivery time?

Usually within 7-15 days after the deposit.

3. What is your power supply?

We will adjust according to your countries power supply, such as 220V, 380V and 415V.

4. What is your Min order quantity?

One set. Our customers can be end users, retailers and wholesalers.

5. What is machine warranty time?

The warranty time is 2 years for the machine and tools, the vulnerable parts warranty time is 1 year.

6.How do you ship the tools and machines and how long does it take to arrive?

We usually ship by sea. It usually takes 30 days to arrive. Airline shipping also optional.

Product Categories : Press Brake > WE67K

Premium Related Products